The Revolutions that got us Here

“How to think about Advancing Industry and Quality” expands on the fundamental concepts that underlie the subject and the management of Industry and Quality. Industry and Quality has undergone frequent revolutions in response to the endless procession of change and crises faced by business and manufacturing. Throughout history, people have always been dependent on technology. Of course, the technology of each era might not have the same shape and size as today, but for their time it was certainly something for people to look at. People always use the technology they have available to help make their lives easier and at the same time try to perfect it and bring it to the next level. This is how the concept of the industrial revolution began.

The infographic below summarized the stages of both the major Industrial transformations along with the Quality transformations. Routing through the definitions of quality and the fundamental effects of managing quality. Leading up to the current day concept and framework of Operational Excellence. Now the industries and transforming to Artificial Intelligence (AI) and its major components. The infographic summarizes with some statistics on how Industry 4.0 (which includes Quality 4.0) is going.

The First Industry Revolution

The first industrial revolution followed the proto-industrialization period. It started at the end of the 18th century to the beginning of the 19th. The biggest changes came in the industries in the form of mechanization. Mechanization was the reason why agriculture started to be replaced by the industry as the backbone of the societal economy.

At the time people witnessed massive extraction of coal along with the very important invention of the steam engine that was the reason for the creation of a new type of energy that later on helped speed up the manufacturing of railroads thus accelerating the economy.

The Second Industry Revolution

Following the first Industrial Revolution, almost a century later we see the world go through the second. It started at the end of the 19th century, with massive technological advancements in the field of industries that helped the emergence of a new source of energy. Electricity, gas, and oil.

The result of this revolution was the creation of the internal combustion engine that started to reach its full potential. Other important points of the second industrial revolution was the development for steel demand, chemical synthesis and methods of communication such as the telegraph and the telephone.

Finally, the inventions of the automobile, and the plane in the beginning of the 20th century are the reason why, to this day, the Second Industrial Revolution is considered the most important one!

The Third Industry Revolution

Another century passes and we bear witness to the Third Industrial Revolution. In the second half of the 20th century, we see the emergence of yet another source of untapped, at the time, energy. Nuclear energy!

The third revolution brought forth the rise of electronics, telecommunications and of course computers. Through the new technologies, the third industrial revolution opened the doors to space expeditions, research, and biotechnology.

In the world of the industries, two major inventions, Programmable Logic Controllers (PLCs) and Robots helped give rise to an era of high-level automation.

The Forth Industry Revolution

For many people, Industry 4.0 is the fourth Industrial Revolution, although there is a large portion of people that still disagree. If we were to view Industry 4.0 as a revolution then we would have to admit that it is a revolution happening right now. We are experiencing it every day and its magnitude is yet unknown.

Industry 4.0 started in the dawn of the third millennium with the one thing that everyone uses every single day. The Internet. We can see the transition from the first industrial revolution that rooted for technological phenomenon all the way to Industry 4.0 that develops virtual reality worlds, allowing us to bend the laws of physics.

The 4 Industrial Revolutions shape the world. Worldwide economies are based on them. There are programs and projects being implemented all around the world, focusing on helping people take advantage of the marvels of the fourth revolution during their everyday lives.

These historical phases along with many other milestones are detailed in a related blog post “Brief History of Quality and Continuous Improvement“. Attached to this post is a infographic showing these major milestones.

The Evolution of Quality 4.0

During the first industrial revolution (late 1700s and early 1800s), innovations in steam and water power made it possible for production facilities to scale up and expand potential production locations. Before then, manufacturing facilities had to be constructed along rivers so waterwheels could be used to generate power.

By the late 1800s, the discovery of electricity and development of infrastructure enabled engineers to build machinery for mass production. Iron ore production increased, enabling machines themselves to be mass produced. In the United States, the expansion of railways made it easier to obtain supplies and deliver finished goods.

The widespread availability of reliable power sparked a renaissance in computing. Toward the end of World War II—around the time when ASQ (then ASQC) was formed—digital computing started to emerge from its analog roots, first with mainframes, then client-server computing and PCs, followed by the advent of the internet and early e-commerce sites. The third industrial revolution came at the end of the 1960s with the invention of the programmable logic controller. This made it possible to automate processes, such as filling and reloading tanks, turning engines on and off, and controlling sequences of events based on the state of the process and changing environmental conditions.

Mobile devices and cloud computing led to a convergence of services, as multiple customer touch points (phone, fax, web, and tablets) gradually blended into the single view of the customer that most organizations now have. Just 20 years ago, organizations were barely able to link your phone calls to customer service, emails and web form queries. Now, it’s taken for granted.

What is Quality?

Intertwined within these revolutions is the concept of quality. The standard of something as measured against other things of a similar kind or maybe the degree of excellence of something. Of the many meanings of the word “quality”, two definitions are of critical importance to managing for quality:

- “Quality” means those features of products which meet customer needs and thereby provide customer satisfaction. In this since, the meaning of quality is oriented in income. The purpose of such higher quality is to provide greater customer satisfaction and to increase income. However, providing more and/or better quality features usually requires an investment and hence usually involves increases in costs. Higher quality in this sense usually “costs more”.

- “Quality” means freedom from deficiencies – freedom from errors that require doing work over again (rework) or that result in field failures, customer dissatisfaction, customer claims, and so on. In this sense, the meaning of quality is oriented to costs, and higher quality usually “costs less”.

In the 1980’s the concept of Big “Q” and Little “q” came about due to the growing quality crisis. The quality “umbrella” had been broadened dramatically. In turn this broadening had changed the meaning of some key words. Adoption of Big “Q” grew during the 1980’s and the trend was irreversible. Those most willing to accept the concept of Big “Q” were Quality Managers and upper management.

Effects of Quality

The Effect on Income. Income may consist of sales of an industrial company, taxes collected by a government body, appropriations received by a government agency, tuitions received by a school, and donations received by a charity. Whatever the source, the amount of the income relates in varying degrees to the features of the product produced by the recipient. In many markets, products with superior features are able to secure superior income. Whether through higher share of market or through premium prices. Products that are not competitive in features often must be sold at below-market prices.

Product deficiencies also can have an effect on income. The customer who encounters a deficiency may take action of a cost-related nature: file a complaint, return the product, make a claim, or file a lawsuit. The customer also may elect instead (or in addition) to stop buying from the guilty producer, as well as to publicize the deficiency and its source. Such actions by multiple customers can do serious damage to a producer’s income.

The Effect on Costs. The cost of poor quality consists of all costs that would disappear if there were no deficiencies – no errors, no rework, no field failures, and so on. This cost of poor quality is shockingly high. In the early 1980’s, there was an estimate that U.S. manufacturing industries, about a third of the work done consisted of redoing what had already been done. Since then, estimates from a sample of service industries suggest that a similar situation prevails in service industries generally.

Deficiencies that occur prior to sale obviously add to producer’s costs. Deficiencies that occur after sales add to customers’ costs as well as to producers’ costs. In addition, they reduce producers’ repeat sales.

How to Manage for Quality

To attain quality, a good starting point is to establish a “vision” for the organization, along with policies and goals. Conversion of goals into results is then done through managerial processes – sequences of activities that produce the intended results. Managing for quality make extensive use of three such managerial processes.

- Quality planning

- Quality control

- Quality improvement

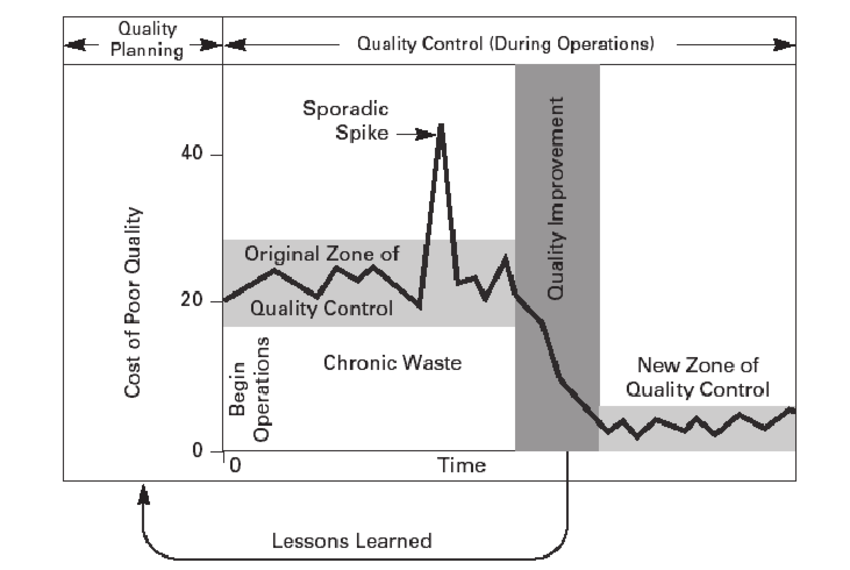

The previous diagram shows time on the horizontal axis and cost of poor quality on the vertical axis. The initial activity is quality planning. The planners determine who the customers are and what their needs are. The planners then develop product and process designs to respond to those needs. Finally the planners turn the plan over to the operating forces.

As operations proceed, it soon emerges that the process is unable to produce good work. Periodic and sporadic spike start to appear during the current process state. In the current state the diagram shows that the cost of poor quality resides at about 20% leaving room for chronic waste – product that must be reworked or processes that must be reperformed.

At some point during operations a decision is then made to address performance through quality improvement. This quality improvement should bring the operational state to a new control zone – hopefully a better control zone. And from the quality improvement event, lessons learned should be feed back to the quality planning process and team so that future improvements can benefit.

Continuing Revolution of Quality

Quality 4.0 and Operational Excellence to Center Stage. Technological advances of the past decade have resulted in the latest industrial revolution often referred to as the fourth industrial revolution or “Industry 4.0.” It’s a revolution driven by the exponential growth of disruptive technologies and the changes those technologies are bringing to the workplace, the workforce, and the markets organizations serve.

“Quality 4.0” is a term that references the future of quality and organizational excellence within the context of Industry 4.0. Quality professionals can play a vital role in leading their organizations to apply proven quality disciplines to new, digital, and disruptive technologies.

What is Organizational Excellence?

Organizational excellence is defined as the ongoing efforts to establish an internal framework of standards and processes intended to engage and motivate employees to deliver products and services that fulfill customer requirements within business expectations. It is the achievement by an organization of consistent superior performance—for example, outputs that exceed meeting objectives, needs, or expectations.

Component Definitions:

- An organization is a group aggregated and combined under specific leadership to function as a single entity for a particular purpose.

- Excellence is a measure of consistently superior performance that surpasses requirements and expectations without demonstrating significant flaws or waste.

Organizational excellence continues the progress established by a foundation such as total quality management, in which all levels of the organization participate in continual improvement.

Organizational Excellence Model and Framework

One program highlighting the traits and attributes of organizational excellence is the Malcolm Baldrige National Quality Award. In the Baldrige Excellence Framework, the attributes of organizational excellence include:

- Leadership

- Strategic planning

- Customer and market focus

- Measurement, analysis and knowledge management

- Human resources/workforce focus

- Process management

- Business results

Another program that highlights a model towards organizational excellence is the Shingo Award. This program puts heavy emphasis on key principles and culture with the clear understanding that people are key to a successful organization. The Shingo Guiding Principles are:

- Respect every individual.

- Lead with humility.

- Seek perfection.

- Embrace scientific thinking.

- Focus on process.

- Assure quality at the source.

- Improve flow and pull.

- Think systemically.

- Create constancy of purpose.

- Create value for the customer.

Managing for Organizational Excellence

Another perspective is to view organizational excellence as the successful integration of technology, infrastructure, and personnel.

Organizational excellence is often the result of transitional and transformational activities. Successful organizational outcomes require deliberate management and improvement in six key areas:

- Information: Metrics, measures, and decision support

- Structure: Roles, responsibilities, and accountabilities of each functional area

- People: Total human capital within the organization

- Rewards: Compensation and incentives

- Learning systems: Knowledge and training

- Work processes: Interaction and linkage of workflows

Organizational excellence is dependent upon gaining sufficient commitment to embrace and apply positive changes in the above areas. Organizational change management is necessary to effectively communicate the changes to those affected in order to minimize uncertainty and obstructions. Collaboration is critical, and the evidence of organizational excellence can be demonstrated across the organization with a balanced scorecard that covers the following perspectives:

- Financial

- Customer

- Internal business processes

- Learning and growth

Organizational excellence is incremental. Different tiers or “maturity levels” should be identified as interim targets for each of the organizational excellence characteristics. By focusing on the performance expectations of an accessible maturity level, employees and stakeholders will be more inclined to make the necessary changes within their control and capabilities. And as maturity levels are reached, participants should be recognized for their efforts.

The image labeled as “Roadmap” located in the gallery shows these four major maturity levels. These are stages of maturity as key organizational excellence components are implemented.

Benefits of Pursuing and Achieving Organizational Excellence

The pursuit of achieving organizational excellence can strengthen the overall prestige of an organization both internally and externally. Any additional costs to infrastructure and overhead have the potential to be repaid with greater returns resulting from engaged employees, satisfied customers, and more efficient operations.

As detailed in “The Impact of Baldrige on Organizational Performance”, a survey of 273 Baldrige Performance Excellence program applicants showed a benefit-to-cost ratio of 3.0 to 1 associated with using the Baldrige Excellence Framework, a 107 to 1 benefit-to-cost ratio when considering financial gains associated with increased customer satisfaction, and a ratio of 820 to 1 when also considering financial gains associated with increased value of sales in excess of resource costs.

Establishing and Implementing Quality 4.0 Principles

To achieve excellence through quality is to embrace the future of quality. It is paramount that quality professionals help their organizations make the vital connection between quality excellence and their ability to thrive in disruption, using quality principles to enable transformation and growth.

People

Quality 4.0 is more than technology. It’s a new way for quality professionals to manage quality with the digital tools available today and understanding how to apply them and achieve excellence through quality. By speaking the digital language and making the case for quality in disruption, quality professionals can elevate their role from enforcers to navigators to successfully guide organizations through digital disruption and toward excellence.

Process

As more work is automated the need for flawless processes remains the same, if not more important. Existing processes will be broken and the need to educate the next generation of workers to implement new processes and strategies will be vital to not only the quality professional but also business operations. Quality is a vital link and should be included at the strategic level for sustainability during digital transformation.

Technology

Technology is growing 10 times faster than it used to, and organizations’ platforms, such as processes, systems, data, operations and governance, must keep pace. Technology also is a great leveler because it gives any individual with the right idea and intent the capability that previously was available only to large organizations. Quality professionals must move from data analyst roles to data wrangler roles by engaging with new technologies, understanding these technologic advancements and the potential outputs they create, and determining how and when to use them.

Quality 4.0 Tools

Deploying an organization’s digital strategy won’t be without hiccups. There will be some common challenges that cut across all industries and digital maturity levels, and others that are specific to an organization. In addition to the timeless and well-known quality tools and principles, the Quality 4.0 tools below should be leveraged to alleviate these challenges when implementing and deploying systems to support digital transformation.

- Artificial intelligence: computer vision, language processing, chatbots, personal assistants, navigation, robotics, making complex decisions.

- Machine learning: text analysis, recommendation systems, email spam filters, fraud detection, classifying objects into groups, forecasting.

- Neural networks: pattern recognition, unnatural pattern recognition, neural networks for each pattern, parameter estimation, change-point estimation.

- Deep learning: image classification, complex pattern recognition, time series forecasting, text generation, creating sound and art, creating fictitious video from real video, adjusting images based on heuristics (make a frowning person in a photo appear to smile, for example).

- Blockchain: increasing transparency and auditability of transactions (for assets and information), monitoring conditions so transactions don’t occur unless quality objectives are met.

- Big data: infrastructure (such as MapReduce, Hadoop, Hive, and NoSQL databases), easier access to data sources, tools for managing and analyzing large data sets without having to use supercomputers.

- Enabling technologies: affordable sensors and actuators, cloud computing, open-source software, augmented reality (AR), mixed reality, virtual reality (VR), data streaming (such as Kafka and Storm), 5G networks, IPv6, IoT.

- Statistics and data science: the practice of bringing together heterogeneous data sets for making predictions, performing classifications, finding patterns in large data sets, reducing large sets of observations to most significant predictors, applying sound traditional techniques (such as visualization, inference and simulation) to generate viable models and solutions.

Quality 4.0 Value Propositions

New technology should always be introduced with a clear articulation of the desired benefits it will deliver and, sometimes, how it will happen. Value propositions for Quality 4.0 initiatives fall into six categories, listed in order of significance:

- Augment (or improve upon) human intelligence.

- Increase the speed and quality of decision making.

- Improve transparency, traceability, and auditability.

- Anticipate changes, reveal biases, and adapt to new circumstances and knowledge.

- Evolve relationships, organizational boundaries, and concept of trust to reveal opportunities for continuous improvement and new business models.

- Learn how to learn by cultivating self-awareness and other awareness as skills.

Quality professionals are perfectly positioned to propose and lead digital transformation initiatives because they have deep skills in:

- Systems thinking

- Data-driven decision making

- Leadership for organizational learning

- Establishing processes for continuous improvement

- Understanding how decisions affect people: lives, relationships, communities, well-being, health, and society in general.

Smart Factory and Industry 4.0

The term Smart Factory describes an environment where machinery and equipment are able to improve processes through automation and self-optimization. The benefits extend beyond just the physical production of goods to functions like planning, supply chain logistics, and even product development.

Smart Factories make extensive use of Internet of Things (IoT) sensors and devices that connect machines and enable visibility into their condition and factory processes. Increasingly sophisticated analytics and applications based on AI and machine learning handle many of the routine tasks, which enables people to focus on handling exceptions and making higher-level decisions. Robots are expected to populate smart factories for routine work, working alongside people. The following figure and explanations are provided to describe the 5C Architecture of a Smart Factory.

Level 1 — Connection requires acquiring accurate and reliable data from machines and their components. Data sources can be from IoT-based machine controllers, add-on sensors, quality inspections, maintenance logs, and enterprise management systems such as Enterprise Resource Planning, Manufacturing Execution System and Coordinate Measuring Machines. A seamless and tether-free method for data management and communication, proper selection of sensors, and data streaming are important considerations at this level. At this level, a condition-based monitoring system is normally used to monitor machine status.

Level 2 — the Conversion level is the local machine intelligence, where data is processed and converted to meaningful information, such as machine degradation information. Signal processing, feature extraction, and commonly used prognostics and health management (PHM) algorithms — such as self-organizing maps, logistics regression, support vector machines, etc. — and predictive analytics are integrated into this level. The outputs of this level include but are not limited to machine health-related features, health value, and operation regime flags. The goal for this level is to enable self-awareness for the component and machine level.

Level 3 — The Cyber level is where all information confluences and is processed. Peer-to-peer comparisons, information sharing, collaborative modelling, and time machine records of machine utilization and health condition history are analyzed. These analytics provide machines with a self-comparison ability, where the performance of a single machine can be compared with and rated among the fleet and similarities between machine performance and previous assets (historical information) can be measured to predict the future behavior of the machinery. Historical data can also be used to correlate the interfacial effects of multiple features. At this level, a cyber-physical system approach is normally used to assess machine health in different cycles or regimes and further compare it with its peers.

Level 4 – the Cognition level generates a thorough knowledge of the system monitored and provides reasoning information to correlate the effect of different components within the system. Proper organization and presentation of the knowledge acquired for expert users will support proper decisions. Infographic APPs can be used to integrate with machine and user-friendly mobile devices such as smartphones.

Level 5 – the Configuration level provides the feedback from cyberspace to physical space, where actions are taken as either human-in-the-loop or a supervisory control to make machines self-configure and be self-adaptive as well as self-maintained. This stage acts as a resilience control system to apply corrective and preventive decisions that were made in the cognition level.

Summary

The above infographic summarizes this blog post very well by showing the major phases that got us to this point, the deference between Little “q” and Big “Q”, the simple diagram of change into the framework of Organizational Excellence, and then summarizing with some key statistical comparison about the adaptation of Industrial/Quality 4.0 between U.S. and U.K.